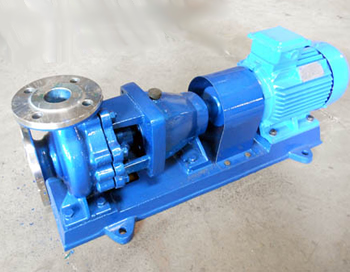

IH type stainless steel chemical pump

IH type stainless steel chemical centrifugal pumps are widely used in chemical, petroleum, pharmaceutical, electric power, food, environmental protection, smelting, mining and papermaking, oil tanker oil unloading, chemical fiber synthesis and other fields, using wear-resistant and corrosion-resistant hard alloy mechanical seals.

Structural features:

The pump cover is fixed on the middle support through the stop, and then the pump cover is clamped in the middle by the connection of the pump body and the stop of the middle support. The pump body is sucked in axially and discharged radially. It can be directly fixed on the base. on. The suspension component is fixed on the intermediate bracket through the stop, and is supported on the base by the suspension bracket. In order to facilitate disassembly, an extended coupling is designed so that the inlet and outlet connecting pipelines, pump body and motor can be disassembled during maintenance. Just remove the middle coupling of the coupling, and then the rotor parts can be withdrawn for maintenance. This is a common structural form on **.

Product Usage:

It is widely used in chemical, petroleum, pharmaceutical, electric power, food, environmental protection, smelting, mining and papermaking, oil tanker unloading, chemical fiber synthesis and other fields. It uses wear-resistant and corrosion-resistant hard alloy mechanical seals.

Performance range of IH stainless steel chemical pump:

Flow rate Q: 6.3~400m3/h

Head H: 5~132m

Speed n: 2900, 1450r/min

With power: 0.55~110KW

Inlet diameter: 50~200mm

High working pressure: 1.6Mpa

There are 29 basic types of IH chemical pumps, of which 22 two-speed (2900, 1450r/min) have been cut and modified by impeller diameters of A and B, reaching 112 specifications.

Performance parameter table:

Pre:None