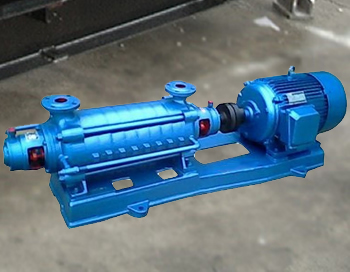

GC type boiler feed water multi-stage pump

GC type horizontal multi-stage centrifugal pump is used for boiler feed water, so it is also called boiler feed water pump. This series of boiler feed water pumps are suitable for transporting clean water with a temperature lower than 110°C or other non-corrosive liquids with physical and chemical properties similar to water.

Overview:

GC boiler feed water multi-stage pump is a horizontal single-suction multi-stage segmented centrifugal pump, which is mainly used for boiler feed water, so it is also called boiler feed water pump. This series of boiler feed water pumps are suitable for conveying clean water with a temperature lower than 110°C or other non-corrosive liquids with physical and chemical properties similar to water. They are widely used for boiler water supply of industrial and mining enterprises and public water supply and urban domestic water supply. GC series pumps are especially suitable for boiler water supply, and can also be widely used in pressure vessel water supply, hot water circulation, high-rise building water supply, farmland irrigation, fire pressurization, hydraulic washing, food, brewing, medicine, chemical industry, aquaculture, environmental protection , Chemical process and machine tool supporting industries, as power equipment for water supply and drainage.

Features of GC multi-stage pump:

The GC type water pump is a multi-stage segmented type. The inlet and outlet of the four models of 1-1/2GC-4GC are respectively on the inlet and outlet sections, and they are all vertically upward. The head can be increased or decreased according to the needs of use. Whether the pump is assembled well or not has a great impact on performance, especially the relative position of the outlet of each impeller and the inlet of the guide wing. The center of the outlet of each suction impeller must be aligned with the center of the guide wing. There is a slight idea about the flow of the pump. Reduced, reduced head, poor efficiency, the pump must be paid attention to when assembling after maintenance, if there is a deviation, it must be adjusted.

The main parts of GC type water pump are shaft, shaft sleeve, inlet section, impeller, sealing ring, middle section, outlet section, balance ring, balance plate and tail cover.

GC type water pump performance parameter table:

|

型号

|

流量

(mз/h) |

揚程

(m) |

轉速

(r/min) |

效率

(%) |

功率(KW)

|

|

|

軸功率

|

電(diàn)機功率

|

|||||

|

1.5GC-5×2

|

6

|

46

|

2950

|

38

|

2

|

3

|

|

1.5GC-5×3

|

6

|

49

|

2950

|

38

|

3

|

4

|

|

1.5GC-5×4

|

6

|

92

|

2950

|

38

|

4

|

5.5

|

|

1.5GC-5×5

|

6

|

115

|

2950

|

38

|

5

|

7.5

|

|

1.5GC-5×6

|

6

|

138

|

2950

|

38

|

6

|

7.5

|

|

1.5GC-5×7

|

6

|

161

|

2950

|

38

|

7

|

7.5

|

|

1.5GC-5×8

|

6

|

184

|

2950

|

38

|

8

|

11

|

|

1.5GC-5×9

|

6

|

207

|

2950

|

38

|

9

|

11

|

|

2GC-5×2

|

10

|

64

|

2950

|

39.6

|

4.4

|

7.5

|

|

2GC-5×3

|

10

|

96

|

2950

|

39.6

|

6.6

|

11.0

|

|

2GC-5×4

|

10

|

128

|

2950

|

39.6

|

8.8

|

15.0

|

|

2GC-5×5

|

10

|

160

|

2950

|

39.6

|

11.0

|

15.0

|

|

2GC-5×6

|

10

|

192

|

2950

|

39.6

|

13.2

|

18.5

|

|

2GC-5×7

|

10

|

224

|

2950

|

39.6

|

15.4

|

22.0

|

|

2GC-5×8

|

10

|

256

|

2950

|

39.6

|

17.6

|

30.0

|

|

2GC-5×9

|

10

|

288

|

2950

|

39.6

|

19.8

|

7.5

|

|

2.5GC-6×2

|

15

|

62

|

2950

|

43.7

|

5.8

|

11.0

|

|

20

|

54

|

2950

|

47.4

|

6.2

|

11.0

|

|

|

2.5GC-6×3

|

15

|

93

|

2950

|

43.7

|

8.7

|

15.0

|

|

20

|

81

|

2950

|

47.4

|

9.3

|

15.0

|

|

|

2.5GC-6×4

|

15

|

124

|

2950

|

43.7

|

11.6

|

22.0

|

|

20

|

108

|

2950

|

47.4

|

12.4

|

22.0

|

|

|

2.5GC-6×5

|

15

|

155

|

2950

|

43.7

|

14.5

|

22.0

|

|

20

|

135

|

2950

|

47.4

|

15.5

|

22.0

|

|

|

2.5GC-6×6

|

15

|

186

|

2950

|

43.7

|

17.4

|

30.0

|

|

20

|

162

|

2950

|

47.4

|

18.6

|

30.0

|

|

|

2.5GC-6×7

|

15

|

217

|

2950

|

43.7

|

20.2

|

30.0

|

|

20

|

189

|

2950

|

47.4

|

21.7

|

30.0

|

|

|

2.5GC-6×8

|

15

|

248

|

2950

|

43.7

|

23.2

|

37.0

|

|

20

|

216

|

2950

|

47.4

|

24.8

|

37.0

|

|

|

2.5GC-6×9

|

15

|

279

|

2950

|

43.7

|

26.1

|

22

|

|

20

|

243

|

2950

|

47.4

|

27.9

|

22

|

|

|

4GC-8×2

|

30

|

86

|

2950

|

51

|

13.8

|

30

|

|

45

|

82

|

2950

|

60

|

16.8

|

30

|

|

|

55

|

76

|

2950

|

62.5

|

18.1

|

30

|

|

|

4GC-8×3

|

30

|

129

|

2950

|

51

|

20.7

|

37

|

|

45

|

123

|

2950

|

60

|

25.2

|

37

|

|

|

55

|

114

|

2950

|

62.5

|

27.2

|

37

|

|

|

4GC-8×4

|

30

|

172

|

2950

|

51

|

27.6

|

55

|

|

45

|

164

|

2950

|

60

|

27.6

|

55

|

|

|

55

|

152

|

2950

|

62.5

|

36.2

|

55

|

|

|

4GC-8×5

|

30

|

215

|

2950

|

51

|

34.5

|

55

|

|

45

|

205

|

2950

|

60

|

42.0

|

55

|

|

|

55

|

190

|

2950

|

62.5

|

45.3

|

55

|

|

|

4GC-8×6

|

30

|

258

|

2950

|

51

|

41.4

|

75

|

|

45

|

246

|

2950

|

60

|

50.4

|

75

|

|

|

55

|

228

|

2950

|

62.5

|

54.1

|

75

|

|

|

4GC-8×7

|

30

|

301

|

2950

|

51

|

48.2

|

75

|

|

45

|

287

|

2950

|

60

|

58.8

|

75

|

|

|

55

|

266

|

2950

|

62.5

|

63.4

|

75

|

|

|

4GC-8×8

|

30

|

344

|

2950

|

51

|

55.0

|

100

|

|

45

|

328

|

2950

|

60

|

67.0

|

100

|

|

|

55

|

304

|

2950

|

62.5

|

73.0

|

100

|

|

|

4GC-8×9

|

30

|

387

|

2950

|

51

|

62.0

|

100

|

|

45

|

369

|

2950

|

60

|

75.5

|

100

|

|

|

55

|

342

|

2950

|

62.5

|

82.0

|

100

|

|

|

4GC-8×10

|

30

|

430

|

2950

|

51

|

69.0

|

-

|

|

45

|

410

|

2950

|

60

|

84.0

|

-

|

|

|

55

|

380

|

2950

|

62.5

|

91.0

|

-

|

|